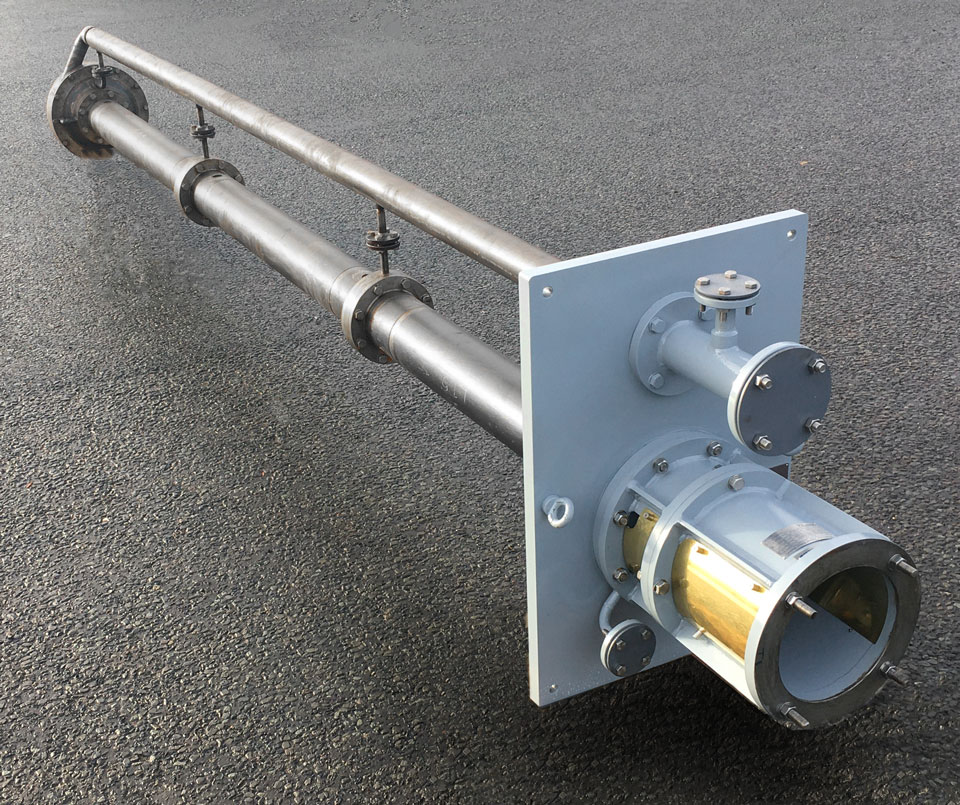

Molten Sulphur Pumps

Molten Sulphur Pumps

PSIL has, for more than 22 years, developed industry-leading steam jacketed pumps for molten sulphur, salts and metals. Its molten sulphur pumps have a design life in excess of 25 years, as standard.

Through continuous research and development, PSIL has refined the features of its MSP technology, using direct feedback from clients who have deployed the equipment in operations worldwide.

PSIL molten sulphur pumps feature:

- Stiff shaft, 60mm diameter construction

- API 610 figure-32 maximum spacing between shaft guide bearings as a minimum standard

- • Line-shaft bearings with fully-floating bushes to balance wear and extend lifespan

- Under-ground line-shaft bearing sleeves with stellite 12-weld overlays, prior to grinding to finished size if the unit is carbon steel

- Extensive steam jacketing, minimising cold spots and enabling sulphur to drain down during servicing

- Open impellers, preventing sulphur blockages by increasing tolerance for entrained solids and gas, while accommodating viscosity variation

- One-piece shafts available up to 4 metres and, for longer applications, two-piece construction would be utilised

- Discharge nozzles rated to loads twice API 610 Table 5

- Circular mounting plates to ANSI B16.5 RF standard or rectangular to suit pit openings

All materials are of dense, homogenous wrought construction – PSIL does not build from castings.

Finishing vertical pump wet ends with stainless steel is increasingly popular, significantly extending the lifespan of pump sets, particularly for sulphur environments.